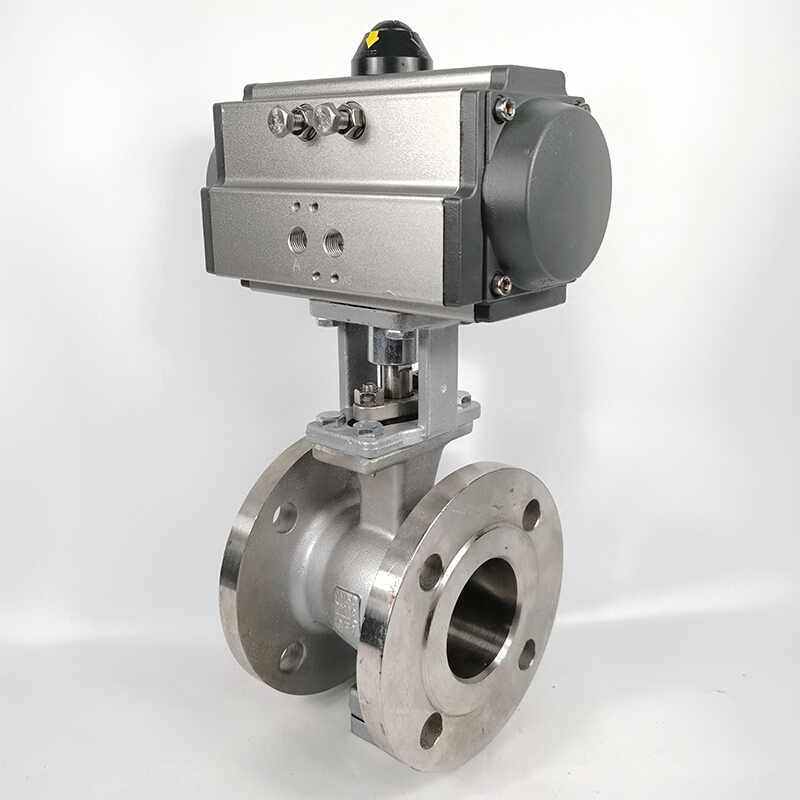

| Short Description: | A V-Port Ball Valve has either a 'v' shaped seat or a 'v' shaped ball. This allows the orifice to be opened and closed in a more controlled manner, with a closer to linear flow characteristic. This type of valve is also known as a control valve because the flow velocities need to be controlled depending on the application. |

| Size Range: | DN 25~250mm NPS 1”-10” (Wafer)DN 25~500mm NPS 1”-20” (Flange) |

| Press. Rate: | PN 10/16/25/40/63ANSI 150/300/600 |

| Temp. Range: | Metal Seat -29...+450℃Resilient Seat -29...+150℃ |

| Seal Tightness: | Metal Seat Class IVResilient Seat Class VI |

| Body Material: | Carbon Steel, Stainless Steel, Special Alloy |

| Ball/Stem Material: | Stainless Steel, Special Alloy |

| Seat Material: | Stainless Steel+STL, PCTFE,PEEK (Flange)Stainless Steel+STL (Wafer) |

| Face to Face: | ISA S75.04, IEC/DIN 534-3-2 (Flange)Factory Standard (Wafer) |

| Flange Standard: | GB/T 9113.1, JB/T 79.1, HG 20592,ASME B 16.34, ISO 7005 (Other drilling on request) |

| Working Type: | When v-port valves are in the closed position, and opening commences, the small end of the 'v' opens first. This allows stable flow control during this stage. The design generally calls for a more robust construction because the higher velocities of fluids might damage standard valves. Although a control valve, v-port valves are not considered as accurate as a globe valve, pressure regulating valve, balancing valve or needle valve. |

| Appliactions: | Ball valves are used in many applications and markets. These can include transmission and storage, gas processing, and industrial, to name but a few. V-Port Ball valves are also commonly used in water treatment, food processing, acid transfer, agriculture, bleach chemicals, leaching acid, waste processing and pharmaceuticals.Pulp and Paper Power Generation Waste water Treatment Plants Chemical Plants Food and Beverage Printing and dyeing Sugar and tobacco Mining Metallurgical Petrochemical etc. |