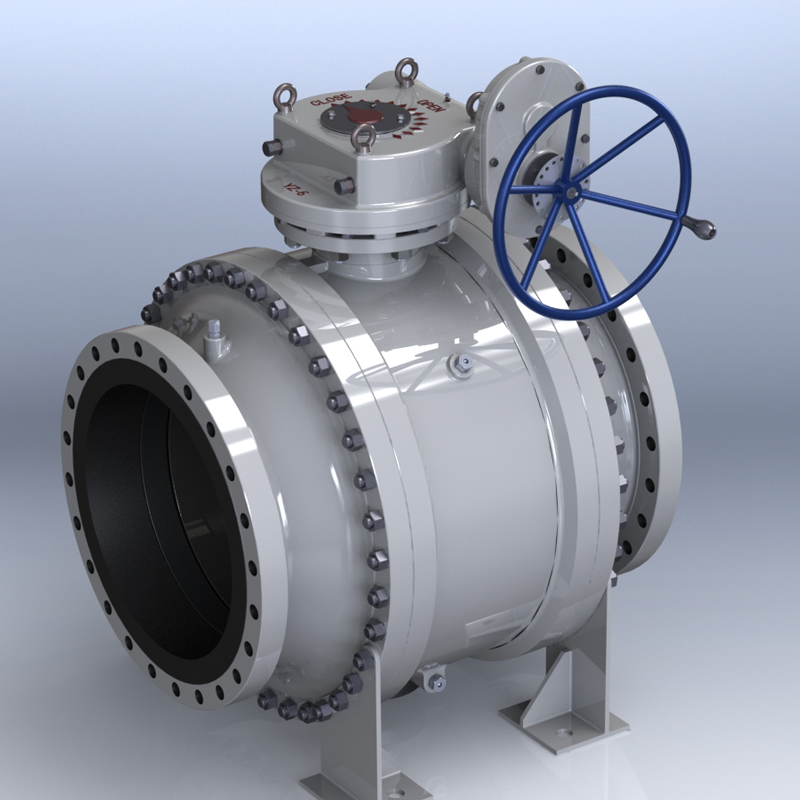

| Size Range: | 2”~36” (50mm~200mm) |

| Press. Rating: | 150LB~2500LB |

| Connection Ends: | Flange, Butt Weld |

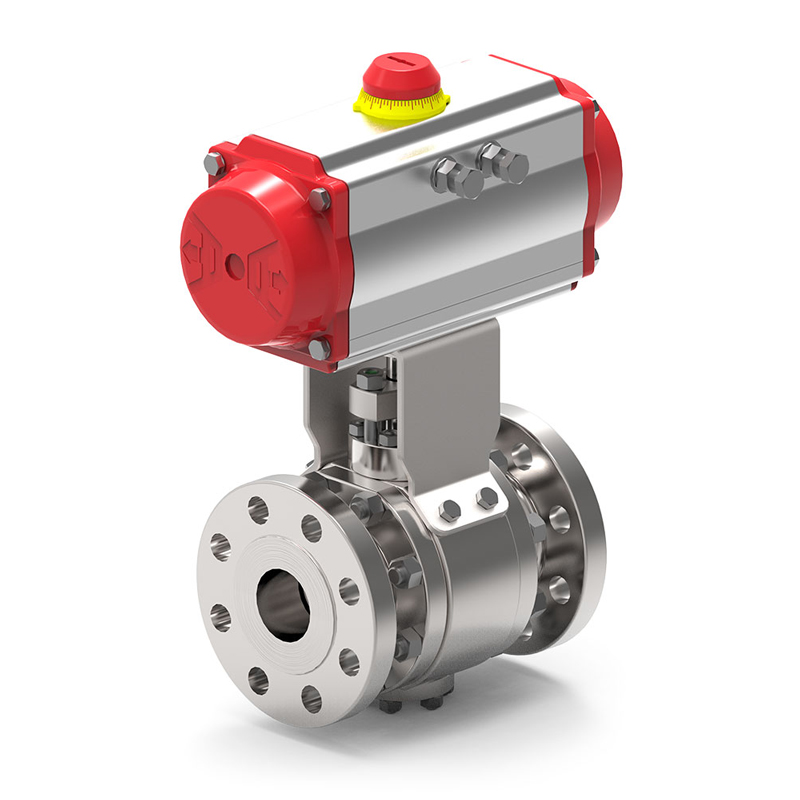

| Operator: | Lever, Gear, Electric, Pneumatic etc. |

| Main Material: | Body Materials: A105 (N), F304, F304L, F316, F316L, F51, Inconel, etc.Ball Materials: A105+ENP, F6a, F304, F304L, F316, F316L, F51, Inconel, etc. Stem Material: 17-4Ph, XM-19, F6a, F304, F316, F51 etc. Seat Material: PTFE, RPTFE, PEEK, NYLON, DEVLON, PPL, PCTFE etc. Spring Material: Inconel X-750, Inconel X-718, SS304, SS316 etc. |

| Standard: | Design: API 6D, ASME B16.34, ISO 14313, ISO 17292 Pressure and Temp. Range: ASME B16.34 Inspection and Test: API598 Flange Ends: ASME B16.5 Butt Weld Ends: ASME B16.25, Fire Safe: API 607 |

| Design Feature: | Anti-blow Out StemAnti-fire Safe DesignAnti-static DeviceDBB/ DIB FunctionEmergency SealingAutomatic Body Cavity ReliefAutomatic Cavity ReliefOptional Locking DeviceLeakage Rate A |

| Working Type: | Ball valves utilise a hollow ball that allows a flow through it when in the open position and isolates when closed. The ball is driven via a spindle that fits into a slot milled into the hollow ball, which in turn is operated by a lever to open and close the ball. The ball valve spindle is encased in the valve body neck and is sealed by a range of neck seals, to prevent leakage, in addition, the ball is sandwiched between two body/ball seats that ensure positive sealing. |

| Applications: | • Ball Valves are used for flow and pressure control and shut off for corrosive fluids, slurries, normal liquid and gases. • They are used in the oil and natural gas industry, but also find a place in many manufacturing sectors, chemical storage, and even residential uses. |